Description

PET-G is available in 17 colors. Coils of 2.3kg. are available (limited color). Samples of 50gr. are available (transparent only). Make your choice! By selecting a variation, only the products available for that variation will appear in the other 2 variations. Example: by choosing the 2.3kg weight variation, only the colors and extrusion diameter available for this variation will appear.

PET-G is a robust filament, high clarity, odor neutral and easy to print. These characteristics, combined with high impact resistance, excellent flexibility and virtually no shrinkage, make PET-G an excellent material combining the advantages of PLA and ABS. It is a hydrophobic filament (does not absorb water). In short, PET-G has many interesting features and is the perfect complement to your filament assortment.

Directions for use:

– The recommended temperature for the heating mat is ± 60 – 80°C. Due to its low tendency to retract, PET-G can also be printed without a heating mat. Despite its low tendency to retract, we recommend using a hook like EZ Stick (for any type of parts), an adhesive such as Kapton or PET (for small parts), glue (for large parts), or even both (Kapton or PET and glue). If you use glue, no need to put it on the entire surface of the part, but only on the contours or areas at risk of retraction.

– PET-G adheres easily to different surfaces.

– PET-G can be used on all filament deposition 3D printers.

Storage tips:

– Our filaments are filmed, in a cardboard box without window filmed also to ensure the good conservation of the product until the moment of use.

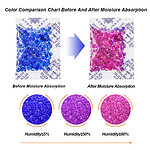

– Store it in a cold and dry environment (15 – 25 ° C), away from light (UV) and under vacuum (to stay dry). We recommend that, after each use, you vacuum it by slipping a silica gel pouch into it and in its box protected from UV. Good storage significantly increases the shelf life of your filament.

Size:

Size Ø Round tolerance

1.75mm. ± 0.05mm. ≥ 95%

Physical properties:

Specific density: ISO 1183 – 1.27gr./cc.

MFR 190°C/2.16kg. : ISO 1133 – 6.4gr./10min.

Tensile strength: ISO 527 – 50mpa.

Performance constraint: ISO 527 – 6%

Elongation at break: ISO 527 – 23%

Traction module: ISO 527 – 2020mpa.

Bending module: ISO 178 – 2050mpa.

Flexural strength: ISO 178 – 69mpa.

Impact resistance Charpy method 23°C: ISO 179 – 8.1kj./m².

Rockwell Hardness: ASTM D785 – 105

Moisture absorption: ISO 62 – 1104ppm.

Transparency: ASTM D1003 – 90%

Thermal properties:

Temp. Printing: DF – 240 ± 10°C

Temp. thermal deformation: ASTM 648 – 70°C

Click here to get the data sheet

Click here for the safety data sheet

Reviews

There are no reviews yet.